SPINDO Hollow GI: Definition, Advantages, Specifications, and Examples of Use

Galvanized Hollow Pipe or often known as Hollow GI Pipe is one of the important materials in the world of construction and manufacturing industries. This article will discuss in full about the superior product from SPINDO, namely Hollow GI, starting from the definition, advantages, to its application in various fields.

What is GI SPINDO Hollow Pipe?

GI SPINDO Hollow Pipe is a square or square steel pipe coated with a layer of

Zinc as a rust protector. The galvanization process (Zinc coating) aims to extend the life of the pipe, making it more resistant to humid, open, or corrosive environmental conditions.

Advantages of GI SPINDO Hollow Pipe

Here are

6 main advantages

of GI SPINDO Hollow Pipe products, namely:

- Certain Dimensions : Each product is manufactured with precise sizes according to standard construction needs.

- Definitely Thick : Consistency in material thickness makes this product strong and sturdy.

- Definitely The Coating : The thick and evenly distributed zinc layer provides maximum protection against corrosion and rust.

- Definitely Precision : Each corner of the pipe is neat and precise, making it easier to install.

- The welds are covered with a layer of Zinc : The joints or welds are also coated with zinc to ensure that the entire surface is protected from rust.

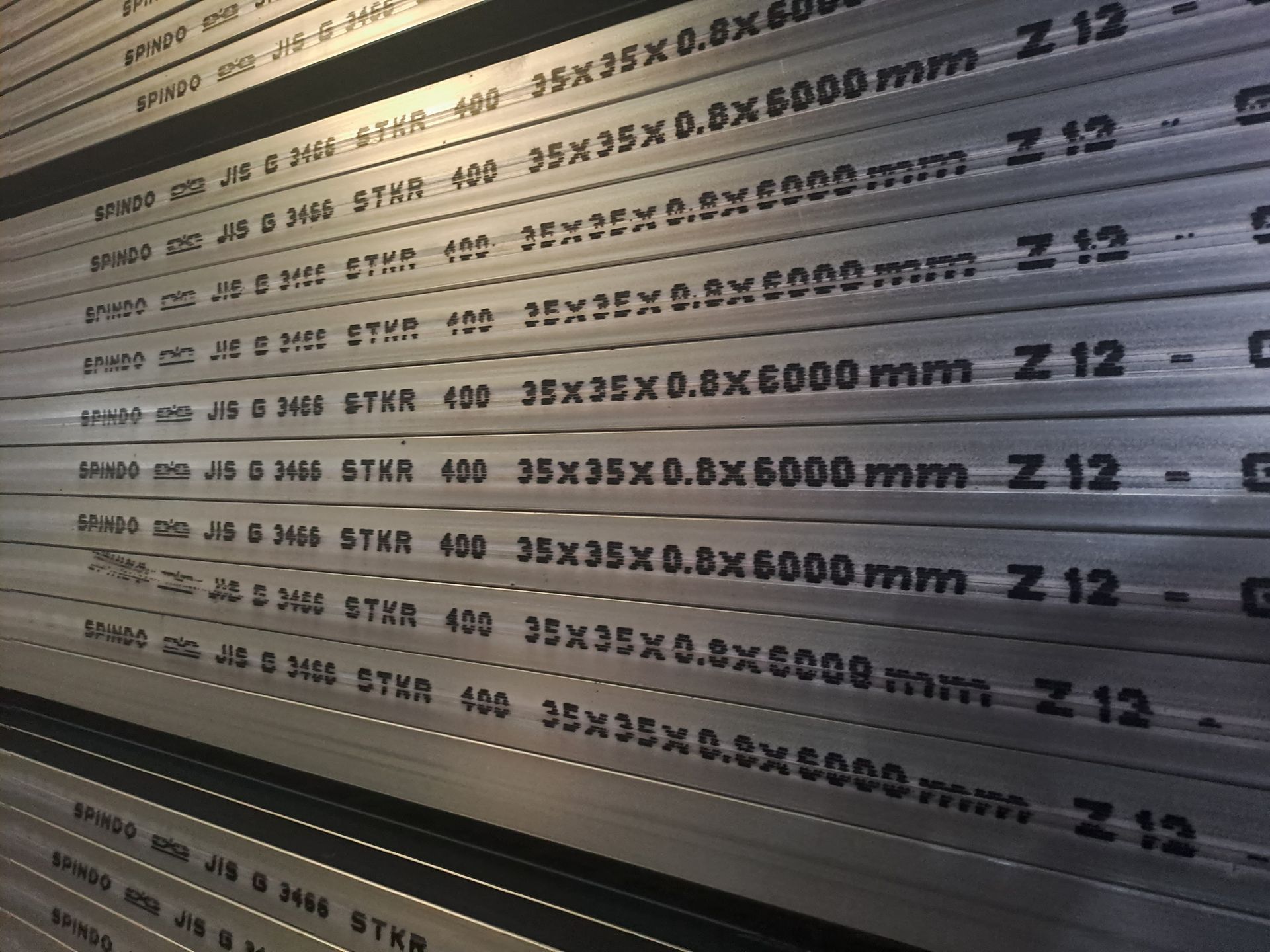

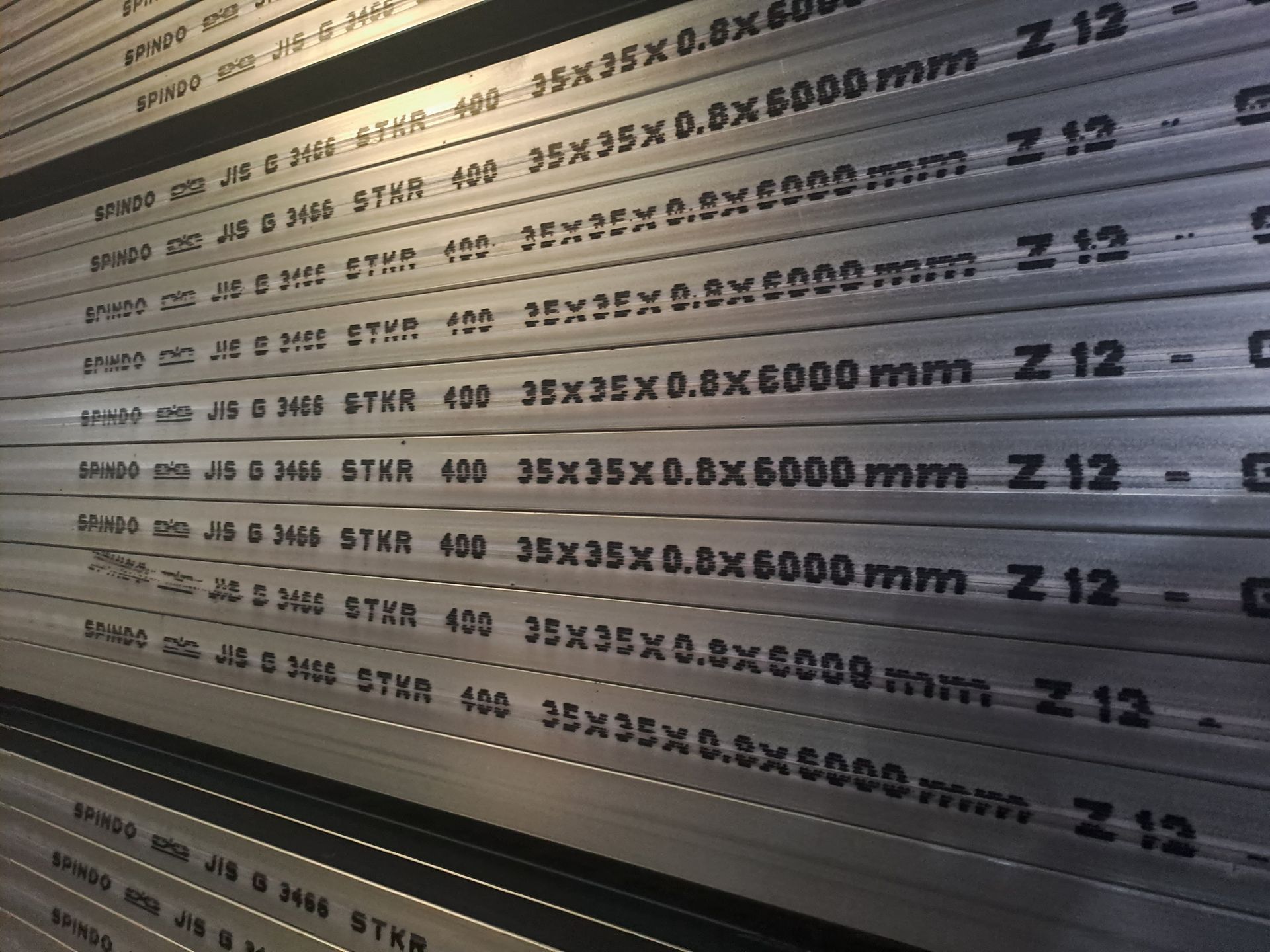

- Marking : Makes it easy to identify products technically and administratively.

Variants of Shape and Size of SPINDO GI Hollow Pipe

With HFW/ERW production technology, SPINDO offers two main shapes with specifications, as follows:

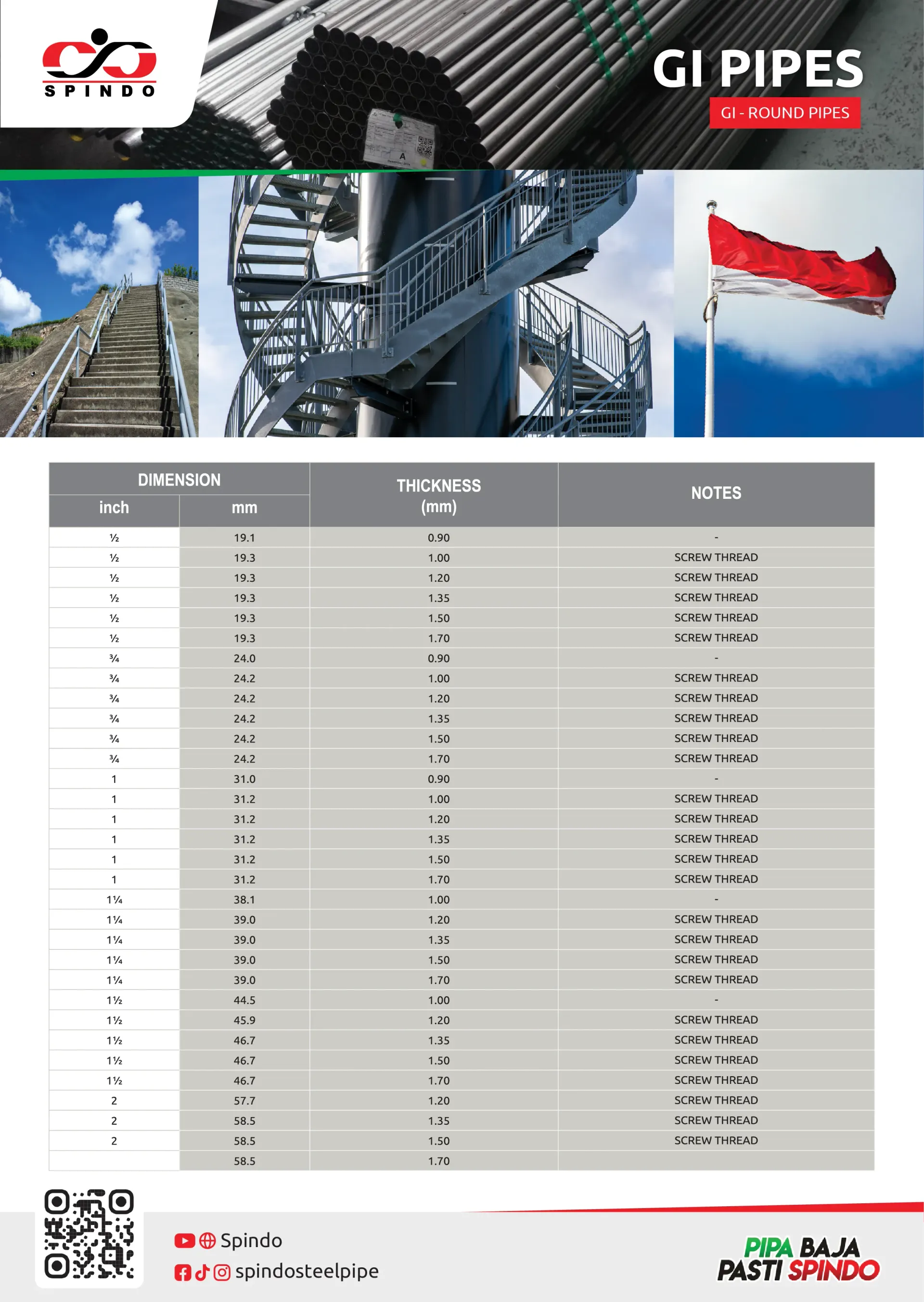

- Round Pipe

Diameter: ½ inch - 2 inches

Thickness: 0.60 mm - 1.70 mm

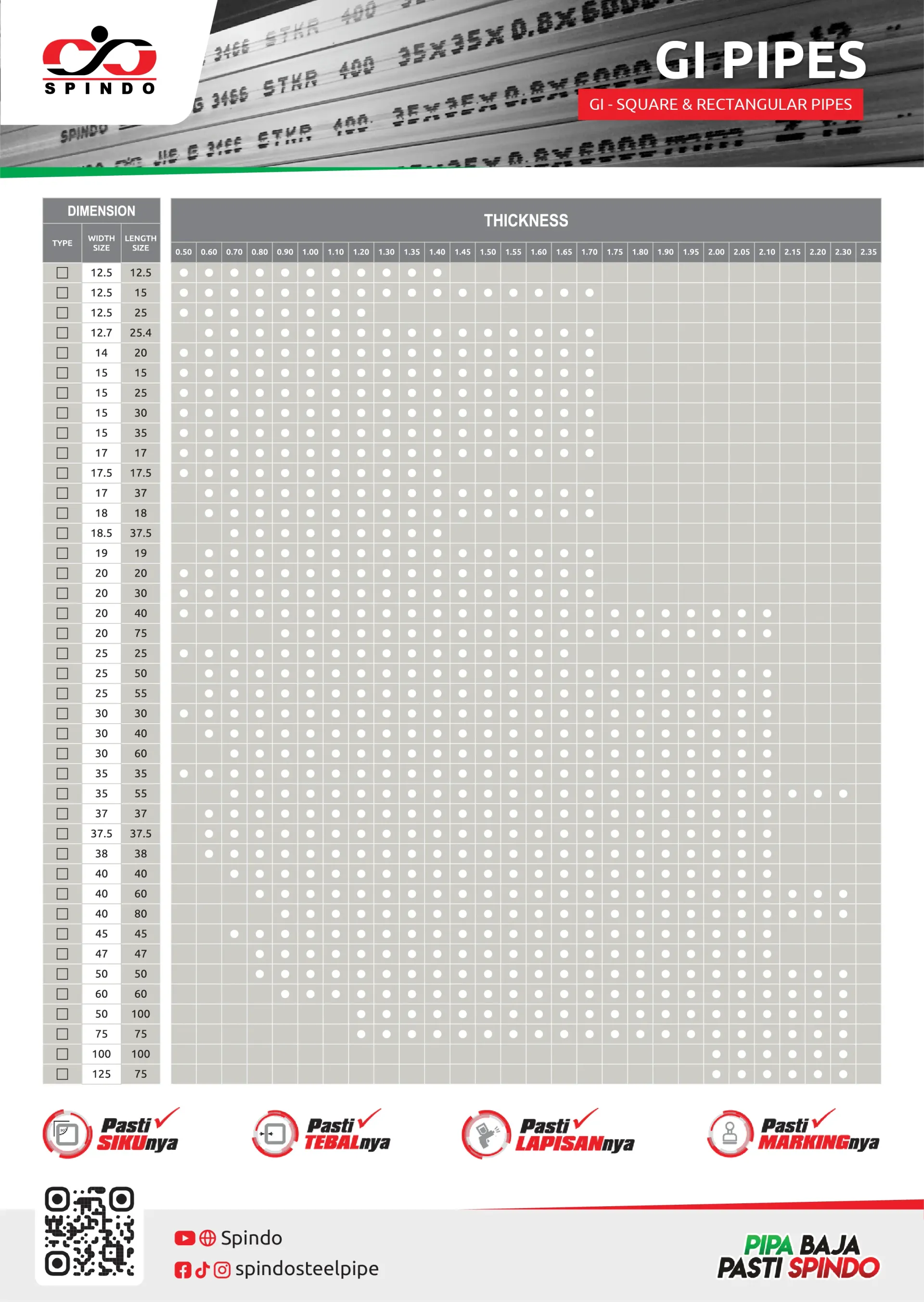

- Square and Rectangular Pipes

Dimensions: 12.5 x 12.5 mm to 100 x 100 mm

Thickness:

0.60 mm - 2.30 mm

Examples of Hollow GI Pipe Applications SPINDO

Here are some examples of the use of Hollow GI in construction projects:

- Building and Housing

- House fence

- Mezzanine

- Interior partition or parapet

- Canopy

- Ceiling

- Stair or window trellis

- Industry and Infrastructure

- Solar panel construction frame

- Agricultural greenhouse structure

- Bus body frame or large vehicle

- Modular house

Conclusion

GI SPINDO Hollow Pipe has many advantages that make it the right choice of material for various construction projects, both indoor and outdoor. Thanks to the protection of the galvanized coating, this product is proven to withstand challenging environmental conditions thus, providing long-term benefits.