A Complete Guide to Choosing Quality API 5L Pipes

API 5L pipes are vital components in a variety of industries, especially those related to fire fighting systems, gas networks, and large construction projects. Choosing the right pipe is crucial to ensure the safety, efficiency, and longevity of the systems that use the pipe. For those of you who are still unfamiliar with API5L pipes but are planning to buy them, this article will provide a complete set of guidelines for choosing quality API 5L pipes.

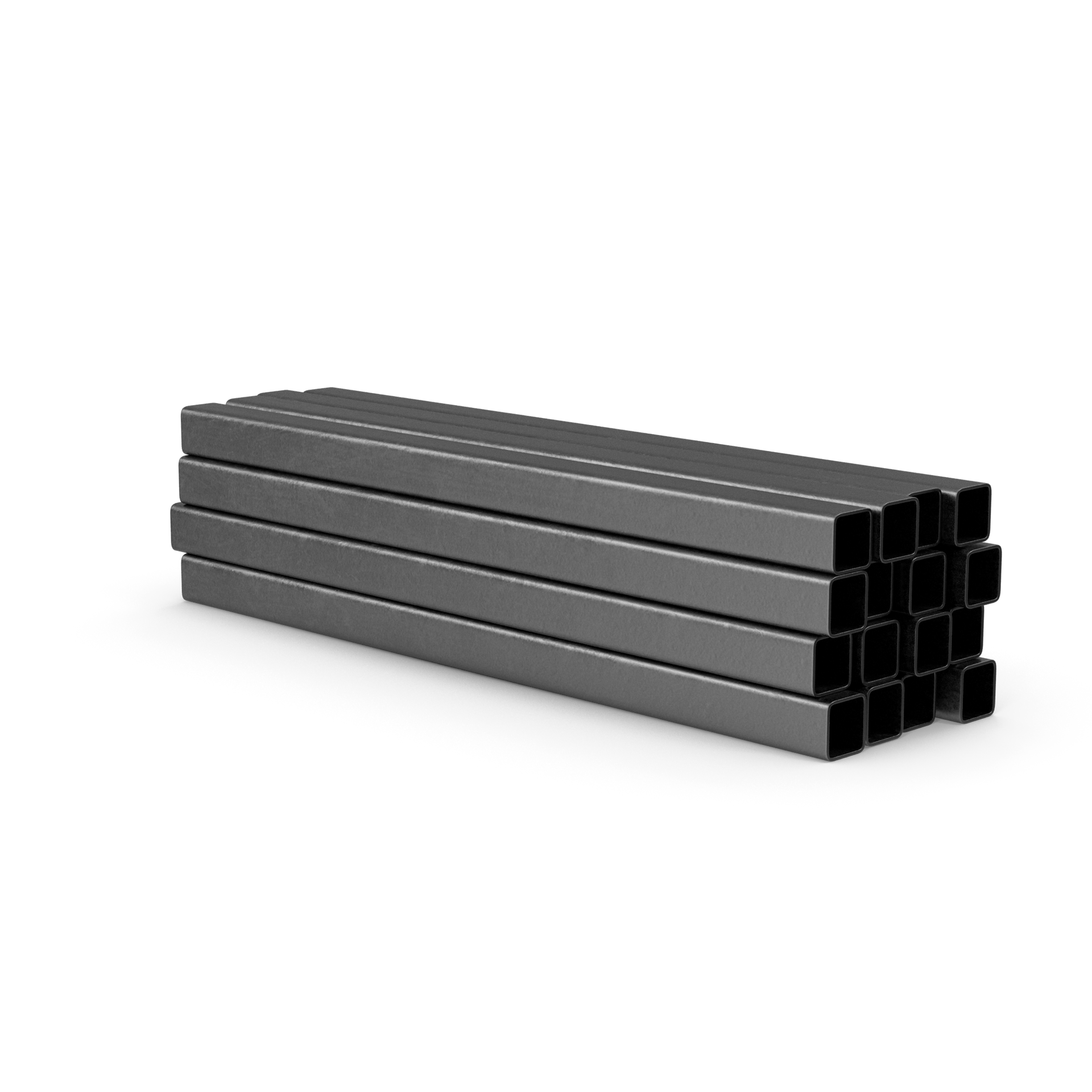

API 5L Pipes for the Oil and Gas Industry

What is an API 5L Pipe?

API 5L pipes are a type of steel pipe specifically designed for transporting liquids and gases under high pressure. The 5L standard refers to specifications from the American Petroleum Institute (API), ensuring that these pipes have high durability and reliability for use in harsh environments.

What Factors Should Be Considered When Choosing API 5L Pipes?

1. Pipe Material

The material of the pipe greatly influences the durability and performance of the API 5L pipe. Pipes made from high-quality steel are generally more resistant to corrosion and high pressure. Be sure to select a pipe with a material composition that suits your project needs. For example, you could opt for carbon steel pipes with galvanized coating for applications in humid environments due to their high rust resistance.

Also read: Characteristics of API 5L Grade B Material You Should Know

2. Technical Specifications

Check the technical specifications of the pipe, such as wall thickness, diameter, and length. API 5L pipes are available in various sizes and specifications. Choose the specification that suits your project requirements to ensure the pipe functions optimally.

3. Corrosion Resistance

Corrosion is one of the main issues that can reduce the lifespan of pipes. Choose pipes with an anti-corrosion protective coating or made from corrosion-resistant materials to ensure long life and safety. Pipes coated with polyethylene or with internal anti-corrosion layers are more resistant to damage from chemical exposure and moisture.

4. Price and Availability

Price is an important factor in pipe selection. However, do not choose pipes solely based on low prices. Also, consider the availability of the pipe in the market and delivery times to ensure your project is not delayed. If the pipe you need is not locally available and requires long delivery times, consider selecting a supplier that can provide equivalent alternatives with faster delivery.

How to Choose High-Quality API 5L Pipes?

1. How to Choose High-Quality API 5L Pipes?

Consult your project needs with experienced experts or consultants in the piping field. They can provide accurate recommendations and advice based on your project requirements.

2. Compare Multiple Suppliers

Compare multiple suppliers of API 5L pipes. Compare the quality, price, and services offered by each supplier to find the best option.

3. Conduct Inspections and Tests

Before purchasing in bulk, conduct inspections and tests on pipe samples. This will ensure that the pipes you buy truly meet the required specifications and standards. For example, you can perform pressure and corrosion resistance tests on pipe samples to ensure the pipe can withstand operating pressure and is not easily corroded.

4. Consider Environmental Factors

Choose pipes that are environmentally friendly and recyclable. This not only helps preserve the environment but can also reduce costs in the long term.

Choosing quality API 5L pipes requires attention to various factors, from material to price. By following this guide, you can ensure that the pipes you select will provide the best performance, safety, and durability for your project needs. Always consult with experts and conduct thorough inspections before making a final decision.

For those looking for high-quality API 5L pipes, you can purchase them from SPINDO. PT Steel Pipe Industry of Indonesia, Tbk. (PT SPINDO, Tbk.) is Indonesia’s largest steel pipe manufacturer with extensive experience in producing various types of steel pipes, tubes, and related products. SPINDO products have earned numerous domestic and international certifications, including API 5L certification, making them a leading supplier of ERW pipes for oil and gas.

SPINDO’s ERW pipes are available in a variety of qualities, thicknesses, and diameters to meet your needs. Made from the best materials and through a strict production process, including casting, roll control, fine-grain processing, and using low-carbon steel, SPINDO’s ERW pipes are guaranteed to be of high quality. Before distribution, the ERW pipes also undergo various tests, such as hydro-testing, ultrasonic weld inspection, micrometer checks, straightness evaluations, and more to ensure the highest quality.

What are you waiting for? Contact SPINDO now by clicking the WhatsApp button in the bottom right corner for more information and to purchase high-quality pipes!