API 5L Grade B Material Characteristics You Must Know

API 5L grade B is one of the steel pipe specifications often used in the oil and gas industry. This material has characteristics that make it very suitable for applications that require high strength and durability. This article will discuss in full and detail the characteristics of API 5L grade B material, as well as its main advantages and applications.

API 5L Grade B for the Oil and Gas Industry

Definition of API 5L Grade B

API (American Petroleum Institute) 5L Grade B is a specification standard covering steel pipes used for transmission pipeline systems. These pipes are utilized to transport natural gas, petroleum, and other fluids in the oil and gas industry. API 5L Grade B refers to a specific strength level within the API 5L specification.

Chemical Composition of API 5L Grade B

API5L grade B has a specific chemical composition that ensures the material's strength and durability. The chemical composition includes:

- Karbon (C): Maksimum 0,28%

- Mangan (Mn): 1,20% maksimum

- Fosfor (P): 0,030% maksimum

- Sulfur (S): 0,030% maksimum

- Silikon (Si): 0,40% maksimum

These element proportions ensure that API 5L Grade B pipes have adequate tensile strength and resistance for use in harsh environments.

Mechanical Properties of API 5L Grade B

The mechanical properties of API 5L Grade B are critical for its application in the industry. The key mechanical properties include:

- Tensile Strength : Minimum 415 MPa

- Yield Strength : Minimum 245 MPa

- Elongation : Varies depending on pipe thickness, but typically around 23%

These properties show that API 5L Grade B can withstand high pressure and mechanical loads in transmission applications.

Production Process of API 5L Grade B

Pipa API5L grade B pipes are manufactured through various processes, such as welding and straightening. Common production methods include:

- ERW (Electric Resistance Welding): This method involves the use of electrical current to weld the pipe edges.

- SAW (Submerged Arc Welding): This method uses an electric arc submerged in flux to produce a strong, high-quality weld.

These processes ensure that API 5L Grade B pipes are resistant to corrosion and cracking, while maintaining high structural integrity.

Main Applications of API 5L Grade B

API5L grade B is used in various applications within the oil and gas industry, including:

- Transmission Pipelines: Transporting crude oil, natural gas, and other petroleum products from production sources to processing locations.

- Distribution Pipelines: Distributing finished products, such as gasoline and diesel, to distribution terminals.

- Subsea Pipelines: Used in offshore installations to transfer oil and gas from the seabed to the surface.

Advantages of API 5L Grade B

Some key advantages of API 5L Grade B material include:

- High Durability: Able to withstand high pressure and harsh environmental conditions.

- Good Tensile and Yield Strength: Provides structural reliability in applications that require endurance.

- Versatility: Suitable for various types of transmission and distribution applications.

API 5L Grade B is a reliable and versatile material choice for the oil and gas industry. By understanding its chemical and mechanical characteristics, as well as its production process, you can ensure its appropriate and optimal use in various applications. Its advantages, including durability, strength, and flexibility, make it a top choice in transmission pipeline systems.

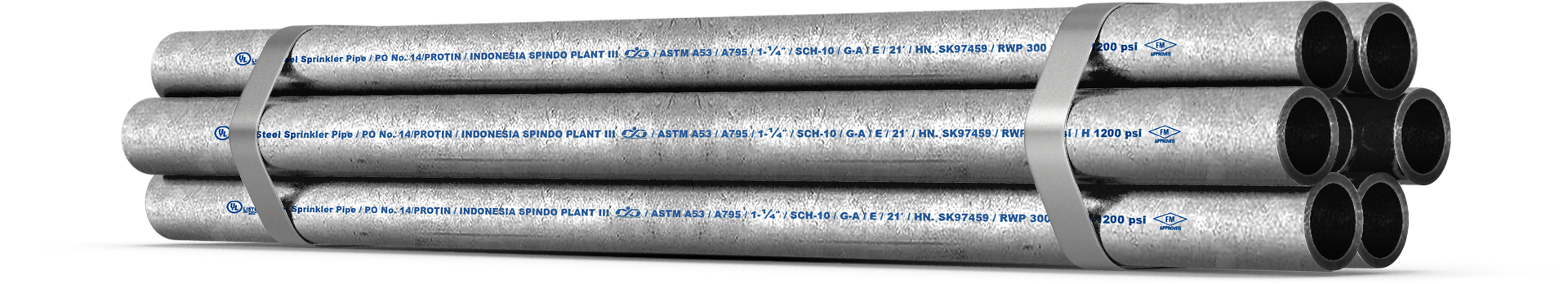

For those in need of high-quality API 5L Grade B, you can purchase it from SPINDO. As the largest steel pipe manufacturer in Indonesia, PT Steel Pipe Industry of Indonesia, Tbk. (PT SPINDO, Tbk.) is experienced in providing a wide range of steel pipes/tubes with various domestic and international certification standards, ensuring their quality, including API 5L Grade B pipes.

For high-quality API 5L Grade B needs, SPINDO offers certified API 5L ERW pipes available in various qualities, thicknesses, and diameters to suit your requirements. Made with the best materials, continuous production processes, stringent quality control, and low-carbon steel, SPINDO’s ERW pipes are guaranteed to be sturdy and durable. Before distribution, SPINDO’s ERW pipes undergo comprehensive testing, such as hydro-tests, ultrasonic weld inspections, micrometer checks, straightness evaluations, and more to ensure the highest quality.

SPINDO has a variety of pipe sizes, adequate capacity, and pipe coating capabilities, making it an ideal choice for the Indonesian market. What are you waiting for? Contact SPINDO now by clicking the WhatsApp button in the bottom right corner for more information and to purchase high-quality pipes!