Expanding Market Reach, SPINDO Holds Customer Gathering in Medan

Introducing Quality Steel Products in North Sumatra, SPINDO holds Customer Gathering

Steel pipe manufacturer, PT Steel Pipe Industry of Indonesia Tbk (Spindo), held a customer gathering at Santika Premiere Dyandra Hotel & Convention, Medan, North Sumatra, on Saturday (24/02/2024). The event was the result of cooperation with PT Sumber Seta Murni as the distributor of Spindo products in the Medan area.

The event was attended by around 300 participants consisting of contractors, end users, iron shop owners, and welding workshop owners. The event was also attended by Spindo Non-Project Marketing Department Head Daniel Sanjoto and Sumber Seta Murni Medan Deputy 2 Eddy. Spindo Deputy Sales Coordinator Non-Project West Region Wega Riaswanti Agustina said that the target of this customer gathering event is to introduce Spindo products in North Sumatra and Aceh.

For information, Medan has an area of about 265.10 square km. The city has beauty and European-style buildings so it is nicknamed the Paris van Sumatra. Because of this, Medan has become a multicultural center of trade, industry and business since the Dutch East Indies era until now. Seeing this potential, Spindo was interested in expanding its steel pipe supply area to Medan and held a customer gathering event. "Consumers do not need to hesitate to buy Spindo products because all products are marked. The goods purchased are also in accordance with the quality that will be used and are certified. Spindo products are definitely superior in quality," said Wega in a press release received by the company.

In line with Wega, the Sales Manager of PT Sumber Seta Murni explained that the customer gathering in Medan was organized to make Spindo products better known to all customers, both large and small. "Most of the needs for iron pipes are available at our place. If there is a special request, Spindo can quickly distribute to Sumber Seta Murni, which is Spindo's distributor in Medan," said Seta.

To convince the participants and customers present, Spindo held a presentation activity related to technical specifications and tests on the strength load of the company's galvanized iron pipe (GI) with similar pipes from other brands.

The activity was guided by a member of the Spindo Marketing Department Sumatra Area, Dony Cristian. In the trial, Dony gave a load to each pipe product. As a result, Spindo's pipe products have better quality and are stronger than competitors' products.

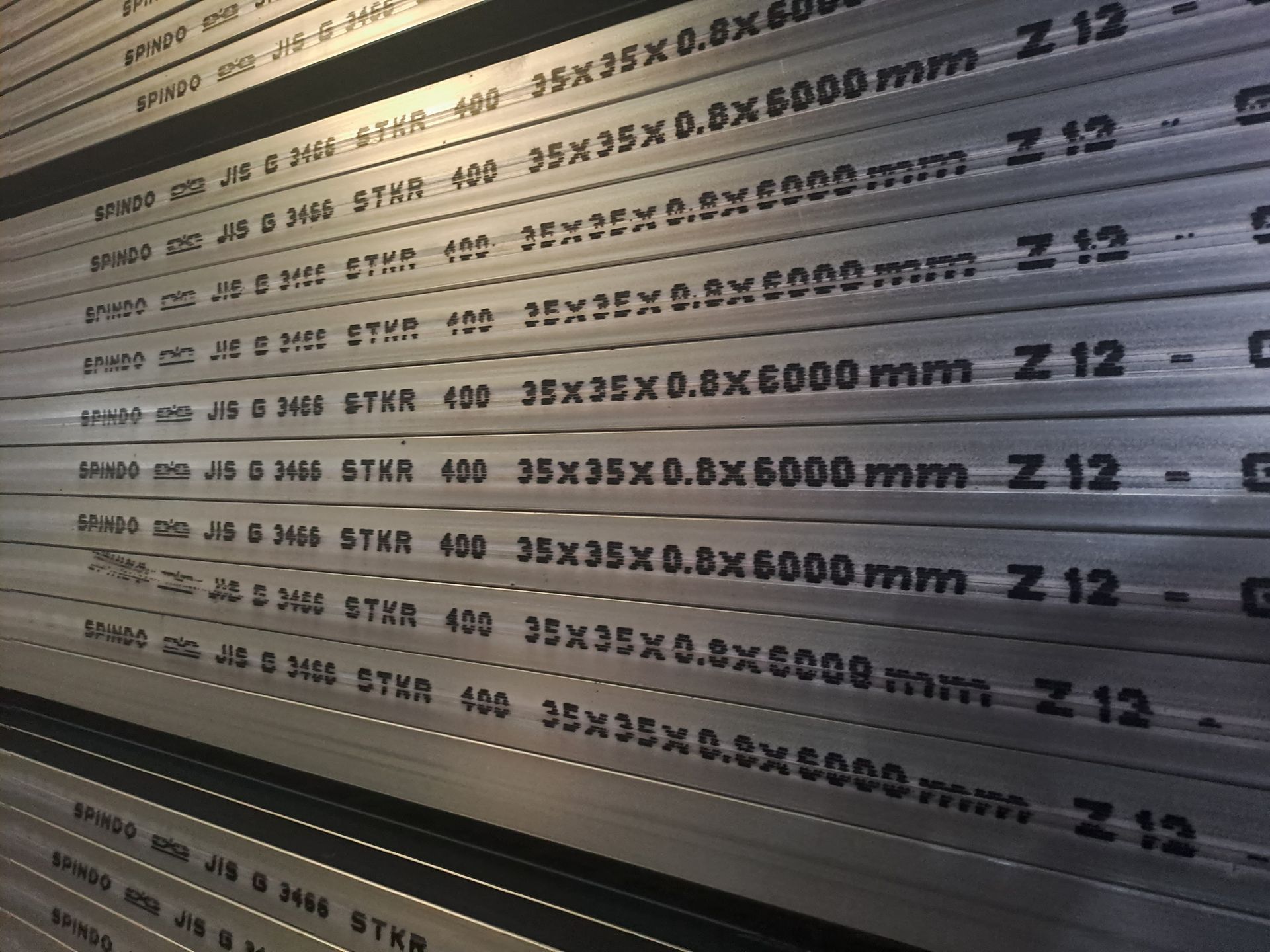

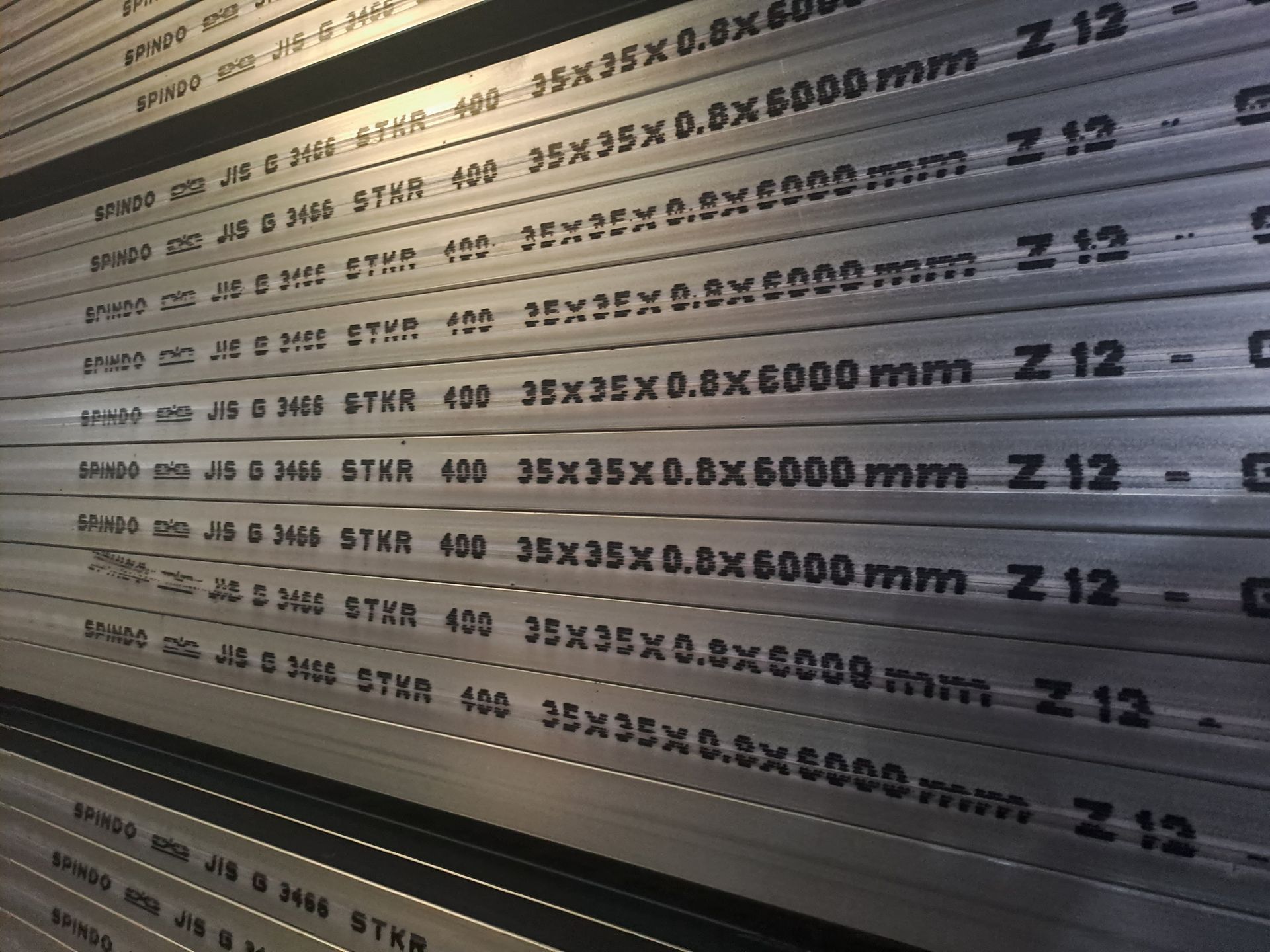

This is because the GI Spindo pipe has a thickness of 120 grams per cubic meter or 16.8 microns. In addition, Gi Spindo pipes have also been coated with zinc coated SNI 07-2053 (Z-12). In the production process, GI Spindo pipes have also been tested through flattening, flaring, and bending processes.

Not only that, each Spindo pipe product is also given a marking that matches its specifications. That way, consumers can choose products according to their expected needs.

Regarding purchases, customers can choose Spindo GI pipes which are available in various sizes in various building material stores. GI Spindo pipes have various advantages, namely high tensile strain (high tensile), have titanium content so that they are strong and minimal maintenance, zinc protection so that they are resistant in corrosive environments and industrial environments, easy installation, and low maintenance costs.

By witnessing the test firsthand, the consumers present were able to prove for themselves the quality of Spindo pipes when compared to other brands. After the presentation, the gathering participants seemed very enthusiastic and immediately asked questions related to the detailed specifications of Spindo products, especially GI pipes.

The strong quality and durability of Spindo's GI pipes was recognized by one of the customers who attended the customer gathering event, Dermawanti. According to her, Spindo's GI pipes have a quality that is far different from competitors' products. Dermawanti himself works as a contractor. From his experience working on projects and using other brands of GI pipes, he admitted that the pipes were often damaged or broken. "After being replaced, it was damaged again. After using Spindo pipes, there were no complaints due to damage again. In addition, the goods needed are always available," said Dermawanti.

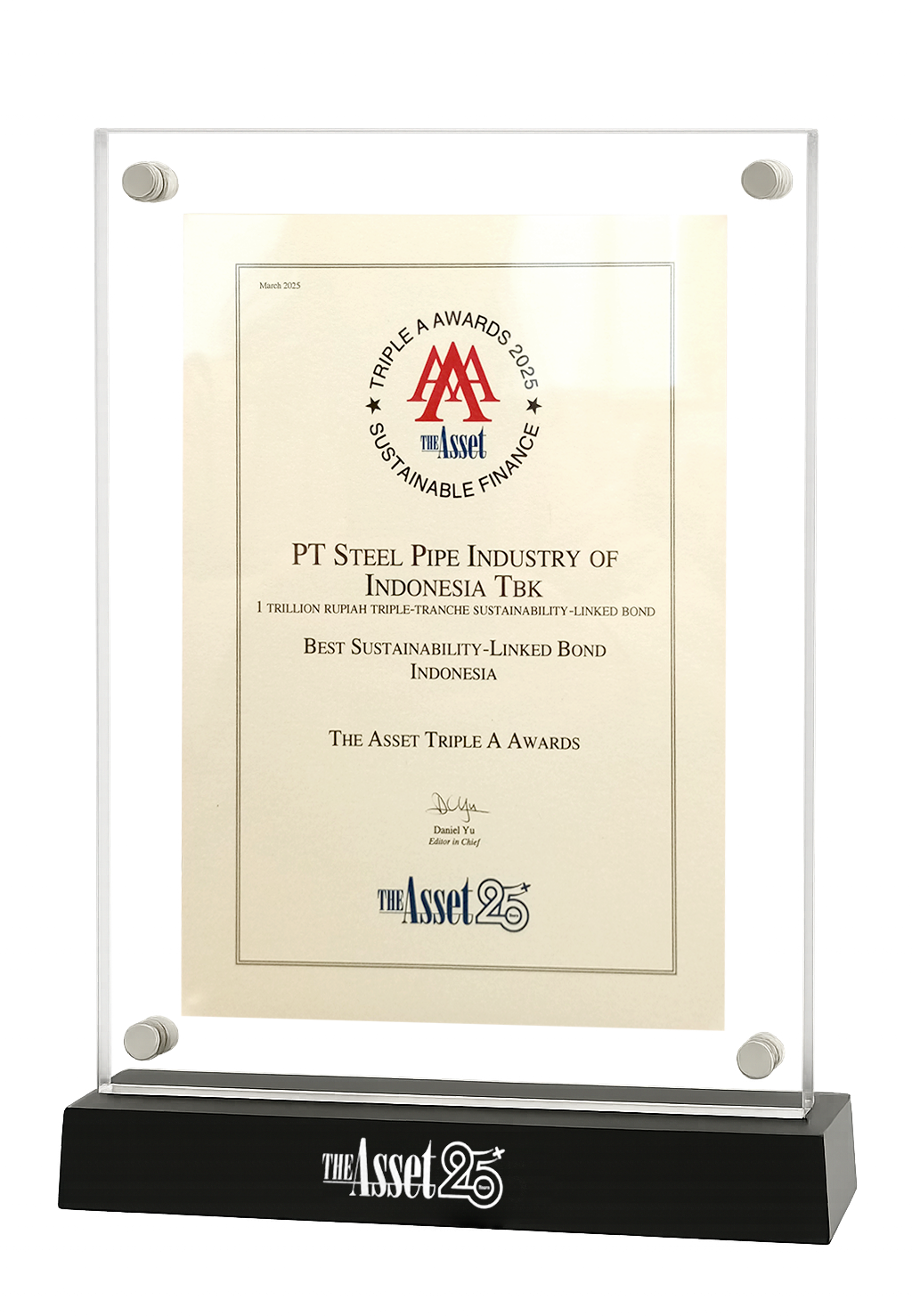

For information, Spindo has been operating since 1971. The company has a steel pipe production capacity of 700,000 tons per year. Currently, Spindo has six factory units, namely units one, two, and three in Surabaya, unit four in Pasuruan, unit five in Karawang, and unit six in Sidoarjo. The various types of pipes produced by Spindo include water pipes, fire sprinkler pipes, structural pipes, oil & gas pipes, GI pipes, and galvanized scaffolding pipes. Spindo pipes have specification information marking on each steel pipe production as a guarantee of production quality. In addition, Spindo Pipes are also manufactured using precision box pipe technology with flat sides and 90 degree angles. Spindo product finishing is also carried out with zinc spray technology (Z12) so that welding marks are not visible.

For more information about Spindo products, please visit Instagram @spindosteelpipe,

Youtube Spindo, Facebook Spindo dan www.linkedin.com/company/spindo.

This article has been published on Kompas.com with the title “Perluas Jangkauan Pasar, Spindo Gelar Customer Gathering di Medan".