Get to know More about Stainless Steel and its Benefits

Stainless steel is one of the most versatile and popular materials used in various industries. From kitchen appliances to building construction, stainless steel has proven itself as a durable, strong, and aesthetically pleasing material. However, what exactly is stainless steel? What makes it so special and what is its composition? In this article, you will get to know more about what stainless steel is, its various types, its benefits, advantages and disadvantages, and its applications in various industries.

Get to know what stainless steel is

Definition of Stainless Steel

What is stainless steel? Stainless steel is a type of alloy metal that is renowned for its resistance to corrosion and tarnishing and is therefore often referred to as stainless steel. This metal contains at least 10.5% chromium, which forms a chromium oxide layer on its surface. This layer prevents further corrosion by protecting the metal underneath. Due to its durability and strength, stainless steel is widely used in various industries, ranging from kitchen appliances to building construction.

Read also: Get to know the term “SUS” on Stainless Steel Pipes

Composition of Stainless Steel

The main composition of stainless steel is iron, chromium, nickel, and molybdenum. The following are some of the key components and their functions:

- Iron (Fe): The basic element in stainless steel.

- Chromium (Cr): Provides resistance to corrosion and oxidation.

- Nickel (Ni): Adds toughness and corrosion resistance.

- Molybdenum (Mo): Improves corrosion resistance in harsher environments, such as seawater.

Types of Stainless Steels

There are several types of stainless steel that are categorized based on their crystal structure and chemical composition, including:

1. Austenitic Stainless Steel

High in nickel and chromium. This type is most common and is known for its resistance to corrosion as well as its ability to maintain strength at high temperatures.

2. Ferritic Stainless Steel

Contains more chromium and less nickel than austenitic. It is less resistant to corrosion but more resistant to cracking.

3. Martensitic Stainless Steel

Contains less chromium and has high carbon. It is hard and strong, but less resistant to corrosion.

4. Duplex Stainless Steel

The combination of austenitic and ferritic structures, provides good strength and corrosion resistance.

5. Precipitation-Hardening Stainless Steel

Known for the high strength achieved through the precipitation hardening process.

Read also: Differences in 5 Types of Stainless Steel Often Used in Industry

Stainless Steel Benefits

- Resistance to Corrosion: Stainless steel does not rust easily, making it ideal for use in wet or acidic environments.

- High Durability: Extremely strong and durable making it suitable for applications that require high mechanical resistance.

- Cleanliness: Easy to clean, making it a top choice for kitchen and medical equipment.

- Aesthetics: Its glossy and modern appearance makes it popular for decorative and architectural applications.

Kelebihan dan Kekurangan Stainless Steel

1. Advantages

- Rust Resistant: Highly resistant to oxidation and corrosion.

- Strong and Durable: Has good mechanical resistance.

- Easy Maintenance: Easy to clean and maintain.

- Environmentally Friendly: Fully recyclable.

2. Disadvantages

- Price: Tends to be more expensive than other metals.

- Welding Process: Some types of stainless steel are difficult to weld.

- Weight: Heavier than some alternative materials such as aluminum.

Applications in Industry

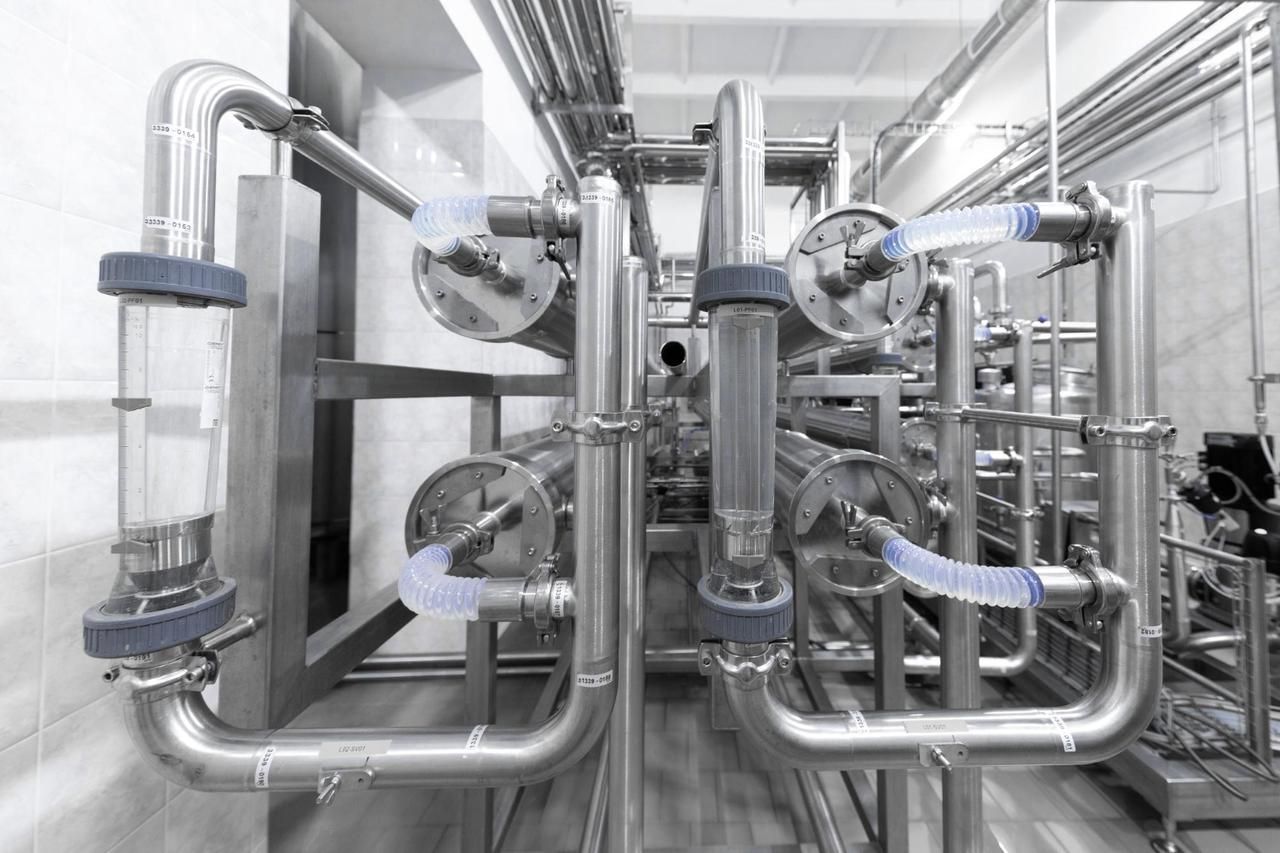

Stainless steel is used in various industries, including:

- Food and Beverage Industry: Kitchen equipment, storage tanks, and distribution pipes.

- Medical Industry: Surgical instruments, operating tables, and other medical equipment.

- Construction: Building facades, bridges, and architectural structures.

- Automotive Industry: Exhaust, engine components, and vehicle trim.

- Marine Industry: Ships, drilling rigs, and other marine equipment due to saltwater resistance.

Stainless steel is a highly versatile material with many advantages that make it ideal for various industrial and household applications. By understanding what stainless steel is, what are its compositions, types, benefits, and advantages and disadvantages, you will find it easier to determine the right steel material for the industrial sector.

For those of you who need austenitic stainless steel, SPINDO is the right choice. SPINDO is a steel pipe manufacturer with the largest production capacity in Indonesia and is experienced in producing various kinds of steel pipes/tubes and various other related products, including stainless steel. SPINDO provides grade 304 and 316 stainless steel which can be used for various purposes, both for ornamental tubes for various daily appliances and industrial pipes.

With its experience and expertise, SPINDO is committed to providing high-quality stainless steel that can meet your needs. Contact SPINDO now by clicking the WhatsApp icon below to get more information and the best offer.