Get to know SPINDO Galvanized Hollow Pipe

Square or rectangular pipe or commonly known as hollow pipe is one of the materials that is often used in the world of construction. SPINDO Galvanized Hollow Pipe is one of the main choices for various structural projects. Known for its superior quality and innovation, these pipes are not just components, but strong foundations for modern construction. Come on, get to know more about the quality of SPINDO Galvanized Hollow Pipes.

1. What is SPINDO Galvanized Hollow Pipe?

SPINDO Galvanized Hollow Pipe or commonly known as SPINDO GI Pipe is a rectangular or square-shaped pipe made of steel and coated by a protector made of Zinc (zinc). The zinc coating is intended to protect steel from corrosion so that its use is more durable. In addition, the strong steel construction makes galvanized pipes resilient and also durable.

2. Advantages of SPINDO GI Pipe

- Good dimensions

SPINDO GI pipes have good dimensions and precision on all sides. Based on the measurement results for SPINDO Galvanized Hollow Pipe measuring 20 mm x 40 mm, getting the results that read on the measuring instrument 20.02 mm x 39.99 mm.

- Good thickness

SPINDO's GI pipe is thick which does not differ much from the original. Measurements for Hollow Pipes with a thickness of 0.8 mm get the results that read on the measuring instrument 0.795 mm

- Zinc Layer minimum Z-12

GI SPINDO pipes have a zinc coating that provides additional protection against corrosion. The result reads a layer thickness measuring instrument that is 18 microns. The layer thickness of SPINDO's Galvanized Hollow Pipe itself uses the Z-12 standard which requires a minimum layer thickness of 120 g / m2 or equivalent to 16.8 microns

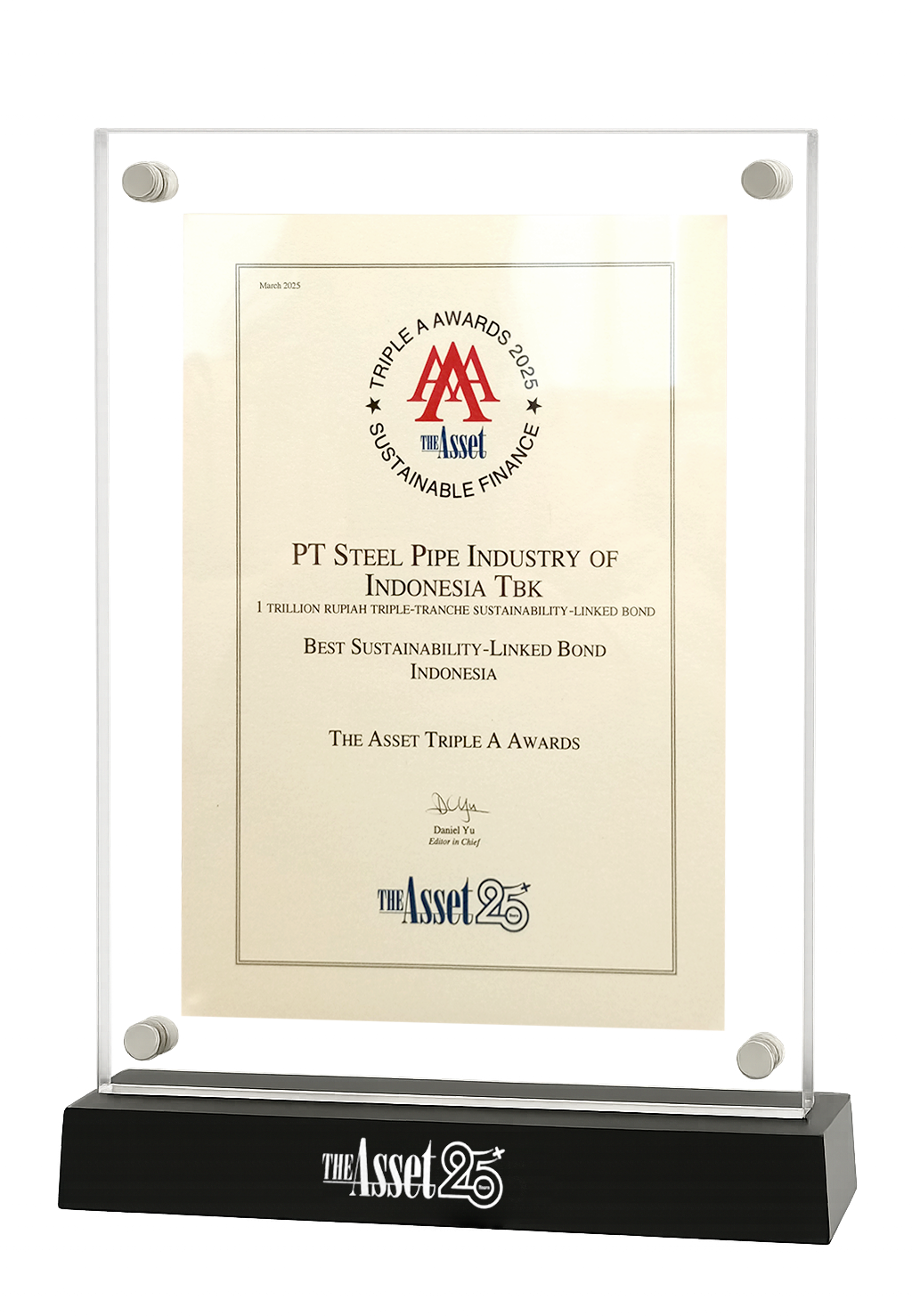

- Good elbows

SPINDO's precise GI pipe size makes the right angle. The results read on the curvature radius measuring instrument (elbow) with dimensions of 20 mm x 40 mm and 0.6 thickness is 1 mm.

- Welded covered with zinc

The welding results of SPINDO's GI pipe are covered by a layer of zinc whose thickness value is in accordance with the Z-12 standard.

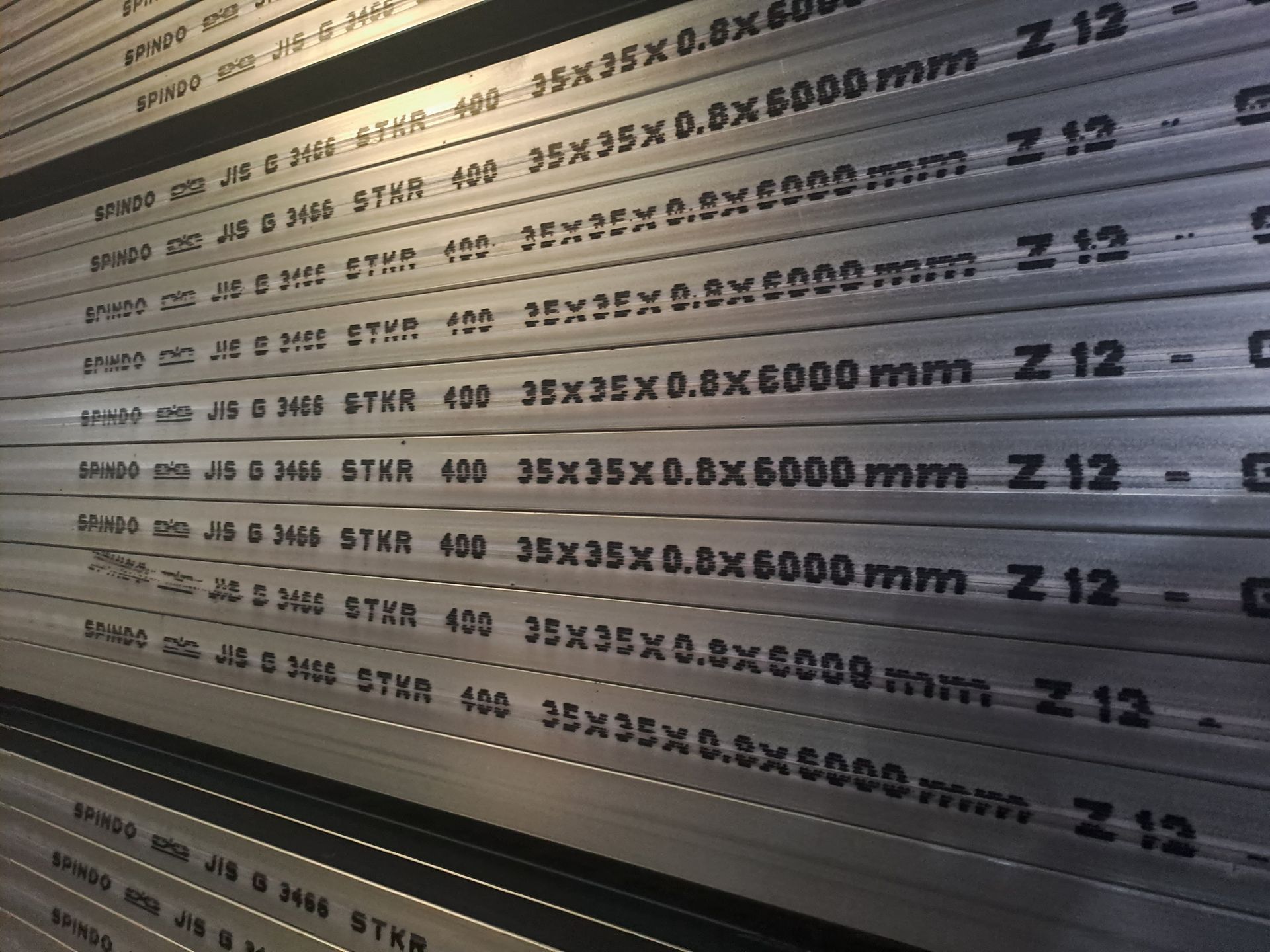

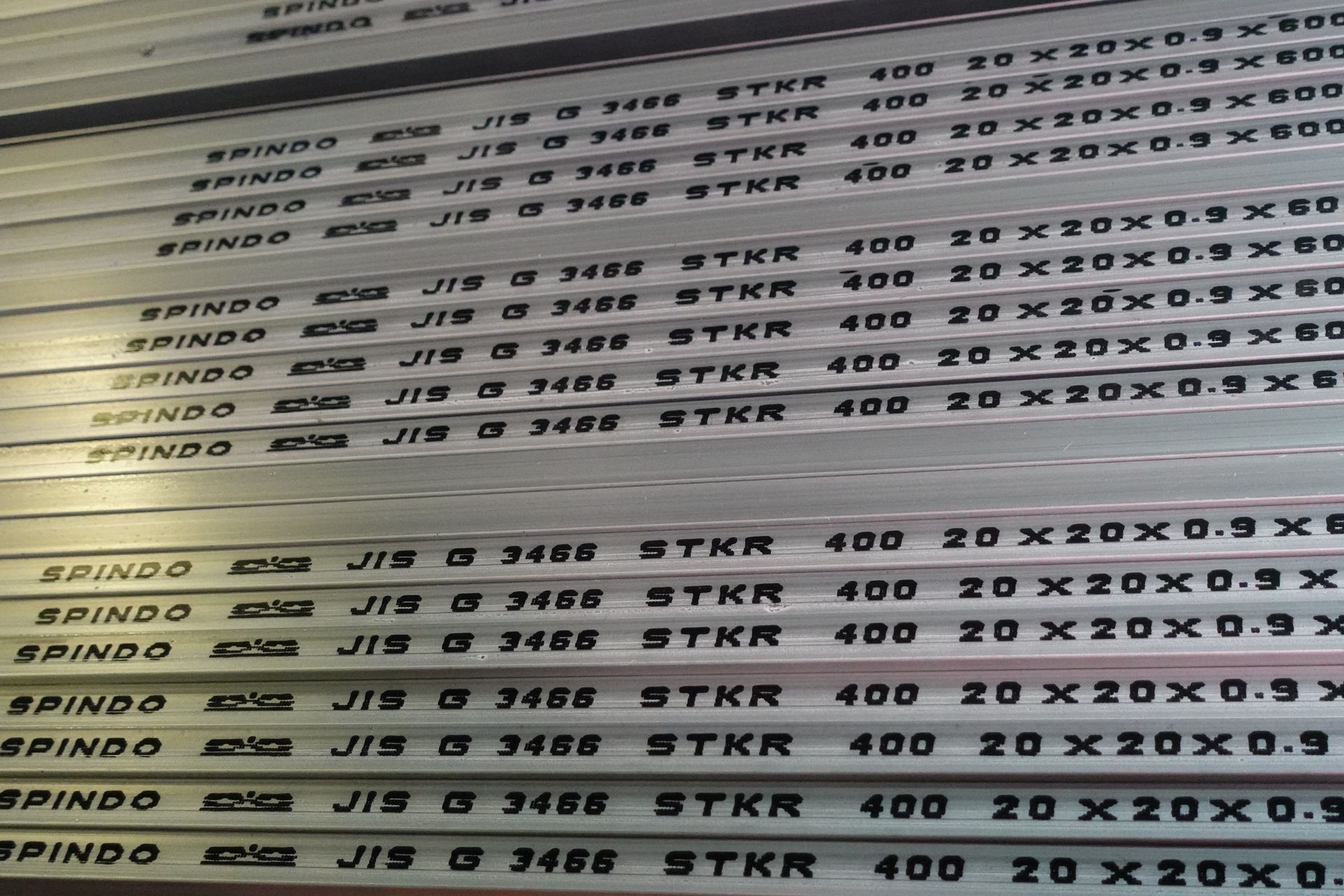

- Have Marking

SPINDO Galvanized Hollow Pipe has Marking that contains actual size dimensions and actual thickness

3. SPINDO Galvanized Hollow Pipe Application

- Light Building Construction

SPINDO galvanized hollow pipe is very suitable for use in light building frames. The advantages of structural strength and corrosion resistance make it usable as a ceiling frame, wall partition frame and much more.

- Fences and Canopies

In the construction of fences or canopies, SPINDO galvanized hollow pipes can provide strong and durable support. The galvanized coating protects the pipes from damage from weather and the external environment.

- Decorative Applications

The variety of dimensions and thickness of SPINDO's galvanized hollow pipe makes it suitable for decorative applications. Many interior designers and architects use this pipe to create unique and durable decorative elements such as those used for table legs, chairs, cabinets and so on.

4. Quality and Certification of SPINDO Galvanized Hollow Pipes

As a leading manufacturer, SPINDO prioritizes the quality of its products. SPINDO will always ensure that every galvanized hollow pipe meets national and international standards. The use of JIS G 3466 standard for SPINDO's Galvanized Hollow pipe is proof of commitment to excellence and safety in every hollow pipe product produced.

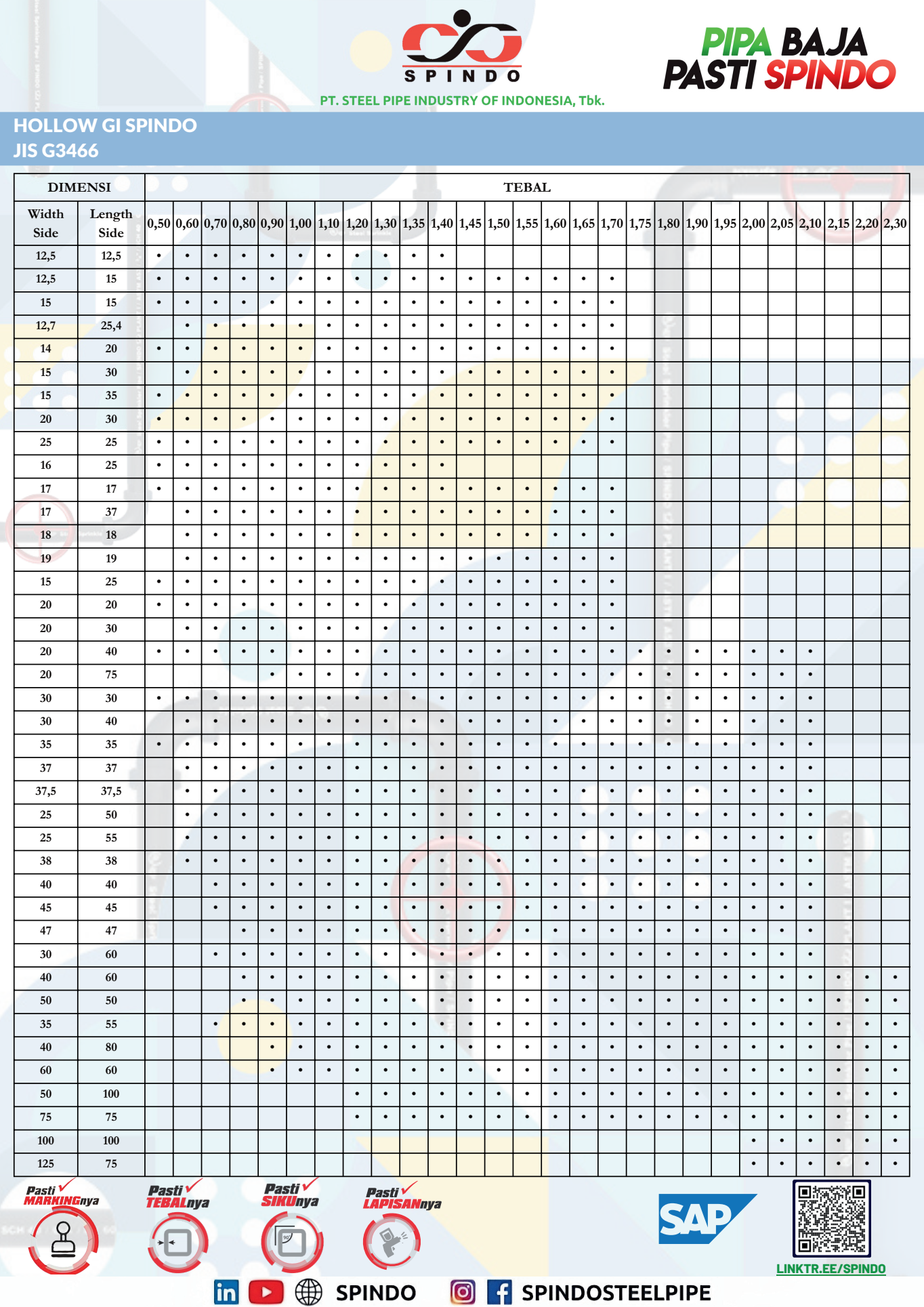

5. Continuous Innovation and SPINDO R&D

SPINDO continues to conduct research and development to introduce the latest innovations in galvanized hollow pipe products. This includes improving production technology, reducing the environmental impact of production and adding a variety of size types to become the most complete manufacturer of galvanized hollow pipes.

6. SPINDO's Contribution to Sustainable Development

By providing high quality products, SPINDO indirectly contributes to sustainable development. The use of durable GI pipes reduces the need for maintenance and replacement, reduces construction waste and negative environmental impacts, and saves the cost incurred for replacing these pipes considering the always fluctuating iron pipe prices.

The Future of SPINDO Galvanized Hollow Pipes

SPINDO's galvanized hollow pipe is not only the best choice in modern construction, but also symbolizes the company's commitment to innovation, quality, and sustainability. By continuously developing products and adhering to the highest standards, SPINDO remains a leader in the pipe industry in Indonesia. Thus, SPINDO galvanized hollow pipe is a smart choice for construction projects that require strength, durability and beauty.